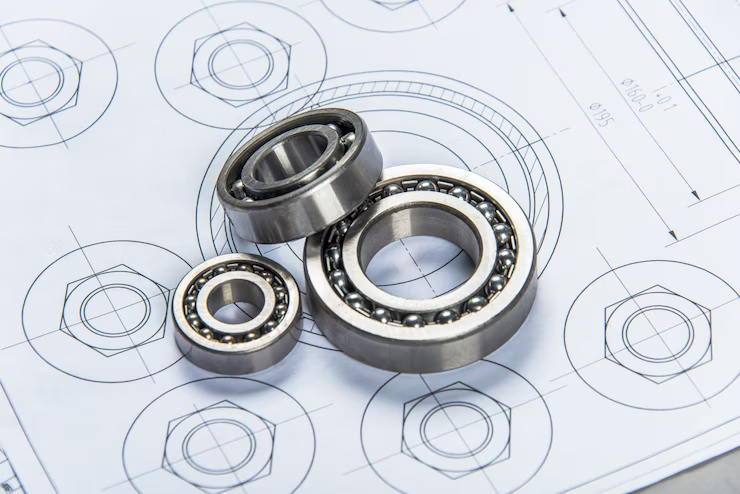

Applications of plain bearings, cylindrical bearings and self-aligning bearings in various industries

Rotating bearings, an indispensable element of many mechanisms, play a key role in ensuring the smooth and efficient functioning of various assemblies. In this section, we will look at how three types of such supports — sliding, cylindrical and spherical — are used in a wide range of industrial applications.

Each of these designs has unique properties that make them ideal for specific operating conditions. Plain bearings provide low friction, which is important for high-speed applications. Cylindrical bearings are characterized by high precision and stability, making them preferred in precision engineering. Spherical bearings, on the other hand, are able to compensate for small misalignments, which is especially important in conditions of vibration or uneven loading.

In this article, we’ll take a closer look at how each type of rotating bearings finds its application in areas such as automotive, aviation, electronics, and more. We will find out what factors influence the choice of a specific support design and how the right choice can increase the efficiency and reliability of equipment.

Main types of supporting elements

In this section we will look at several main types of devices designed to provide rotation and reduce friction between moving parts of mechanisms. These elements are widely used in various fields of technology to increase the efficiency and durability of equipment.

- Hydrodynamic mounts: These devices work on the principle of forming an oil wedge between surfaces, which can significantly reduce friction and wear. They are ideal for high speed applications where stable rotation is required.

- Roller Elements: This type of device uses cylindrical rollers that roll between two surfaces. They provide high load capacity and good rotational accuracy, making them ideal for heavily loaded machinery.

- Ball elements: These devices consist of balls rotating between two rings. They allow rotation in multiple directions and are often used in applications where high dexterity and positioning accuracy are required.

- Self-aligning elements: This type of device has a design that allows it to automatically align itself under load. They are especially useful in conditions of uneven loads or misaligned shafts, providing stable and durable operation.

Each of these types of devices has its own characteristics and optimal areas of application, which makes them indispensable in modern technology and equipment.

Sliding bearings: operating principle

In this section, we will look at the mechanism of operation of one of the types of support elements, which are widely used in various mechanisms to ensure smooth rotation of shafts and axes. The focus will be on the operating principle of these devices, which will help to better understand their effectiveness and applications.

Sliding bearings operate based on the principle of fluid friction, when the surfaces of the rotating shaft and housing are separated by a layer of lubricant. This principle minimizes friction and wear, ensuring high precision and long service life of the mechanism. The table below shows the main components and operating principles of these devices.

| Component | Description |

|---|---|

| Shaft | A rotating element that is installed in a bearing and transmits torque. |

| Liner | A stationary element that is in contact with the shaft and is made of anti-friction material. |

| Lubrication | A fluid that sits between the shaft and the liner, providing surface separation and reducing friction. |

| Frame | The part of the structure into which the liner is installed and which secures the bearing in the desired position. |

The operating principle of plain bearings is to create a hydrodynamic film of lubricant between the shaft and the liner. As the shaft rotates, lubricant is captured in the wedge gap between the surfaces, creating pressure that maintains the shaft at a certain distance from the liner. This process avoids direct metal-to-metal contact, significantly reducing friction and wear.

The design features and materials used in sliding bearings allow them to operate under conditions of high loads and speeds, which makes them indispensable in various fields, from mechanical engineering to electrical engineering.

Cylindrical supporting elements: design features

In this section, we will look at the specific characteristics of one type of mechanical device designed to provide rotation and reduce friction between mating parts. These devices are widely used in various machinery due to their reliability and efficiency.

Main design features

Cylindrical bearings are characterized by the following key features:

- A simple and reliable design consisting of outer and inner rings, as well as rolling elements.

- Using balls or rollers, which ensures low friction and high rotation speed.

- Capable of operating under high loads and speeds, making them versatile for a variety of applications.

Materials and manufacturing technology

High quality materials such as steel, stainless steel or ceramic are used to create the cylindrical support elements. This ensures high strength and wear resistance of the devices. Manufacturing technology includes precision mechanics and quality control, which guarantees durability and reliability in operation.

- Selection of appropriate material depending on operating conditions.

- Precision manufacturing of parts using high-precision machines.

- Assembly with controlled clearances and fits to ensure optimal performance.

In general, cylindrical support elements are an important component of many machines, ensuring their efficient and reliable operation in a variety of conditions.

Self-aligning rotation bearings: advantages of use

In this section we will look at the features and benefits associated with the use of rotation supports that can independently adjust their position. These elements are widely used in various mechanisms, ensuring stability and reliability of operation.

Flexibility in installation and operation

One of the key benefits of self-aligning rotary bearings is their ability to compensate for shaft misalignment. This makes it possible to simplify the installation process and reduce the requirements for the precision of manufacturing of mating parts. As a result, such supports provide smoother and quieter operation of the mechanisms, which is especially important in conditions where high precision and reliability are required.

Resistance to distortions and vibrations

Self-aligning rotation bearings have increased resistance to distortions and vibrations that occur during operation of the mechanisms. Thanks to their design, they can effectively reduce the load on bearing units, extending the life of the entire system. This is especially true for units operating under variable loads and temperature conditions.

In general, the use of self-aligning bearings makes it possible to increase the efficiency and reliability of many industrial installations, making them more adaptable to difficult operating conditions.

Industry Applications

In this section we will look at how various mechanisms that provide rotational motion and support for shafts are used in a wide range of applications. These mechanisms play a key role in improving the efficiency and reliability of many devices and systems.

- Automotive industry: Here, special attention is paid to the use of elements that allow smooth and precise rotation of the crankshaft and other important engine components. These elements are also used in the transmission and suspension, ensuring durability and comfort during vehicle operation.

- Aviation industry: The aircraft industry uses high-tech analogues that can withstand high loads and operate at elevated temperatures. This is critical to the safety and reliability of aircraft engines and other rotating machinery.

- Machine tool industry: In this area, elements are widely used that ensure precise positioning and rotational stability of tools and parts in machine tools. This allows you to achieve high precision and productivity when processing metals and other materials.

- Energy: Generators and turbines of power plants use special analogues that can operate under high loads and in harsh conditions. This ensures stable operation of the equipment, which is extremely important for a continuous supply of electricity.

As you can see, the use of these elements is an integral part of many technological processes, ensuring their efficiency and reliability. The selection of the appropriate element type depends on the specific requirements and operating conditions in each specific area.